MEDICAL

HACK shapes products from all industries worldwide Design and function This is how our expertise enriches the daily lives of many people.

Our injection molds are developed using state-of-the-art technology and are consistently engineered to meet the highest performance requirements. From the very beginning of the development process, all industry-specific conditions relevant to medical production are taken into account. This includes full cleanroom compatibility and a particle-optimized tool design, as well as low-lubrication or lubrication-free concepts, functional coatings that enhance demolding and increase durability, and a completely GMP-compliant tool layout. Through this comprehensive approach, we ensure that our molds are perfectly tailored to the sensitive and demanding conditions within medical manufacturing environments.

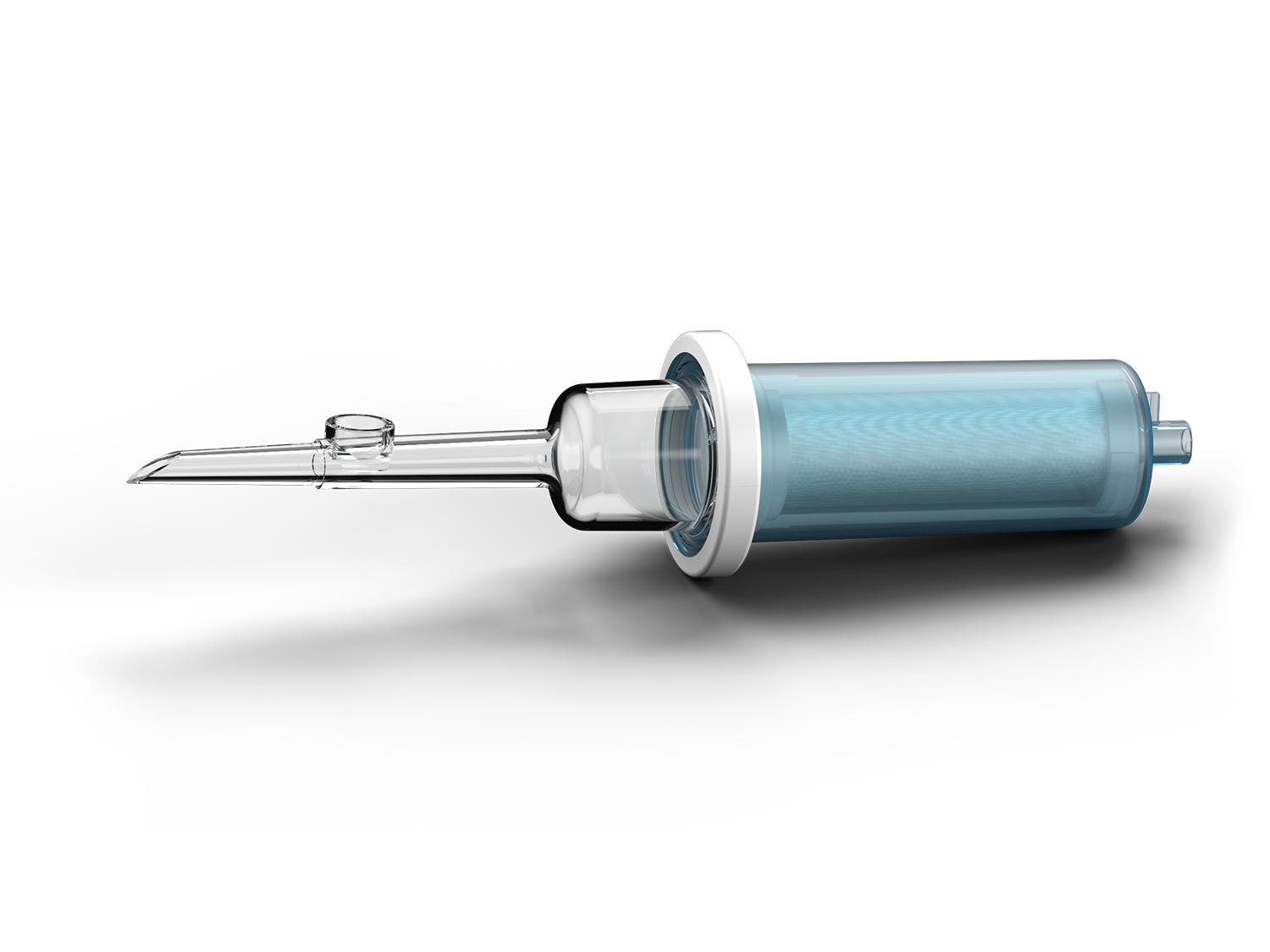

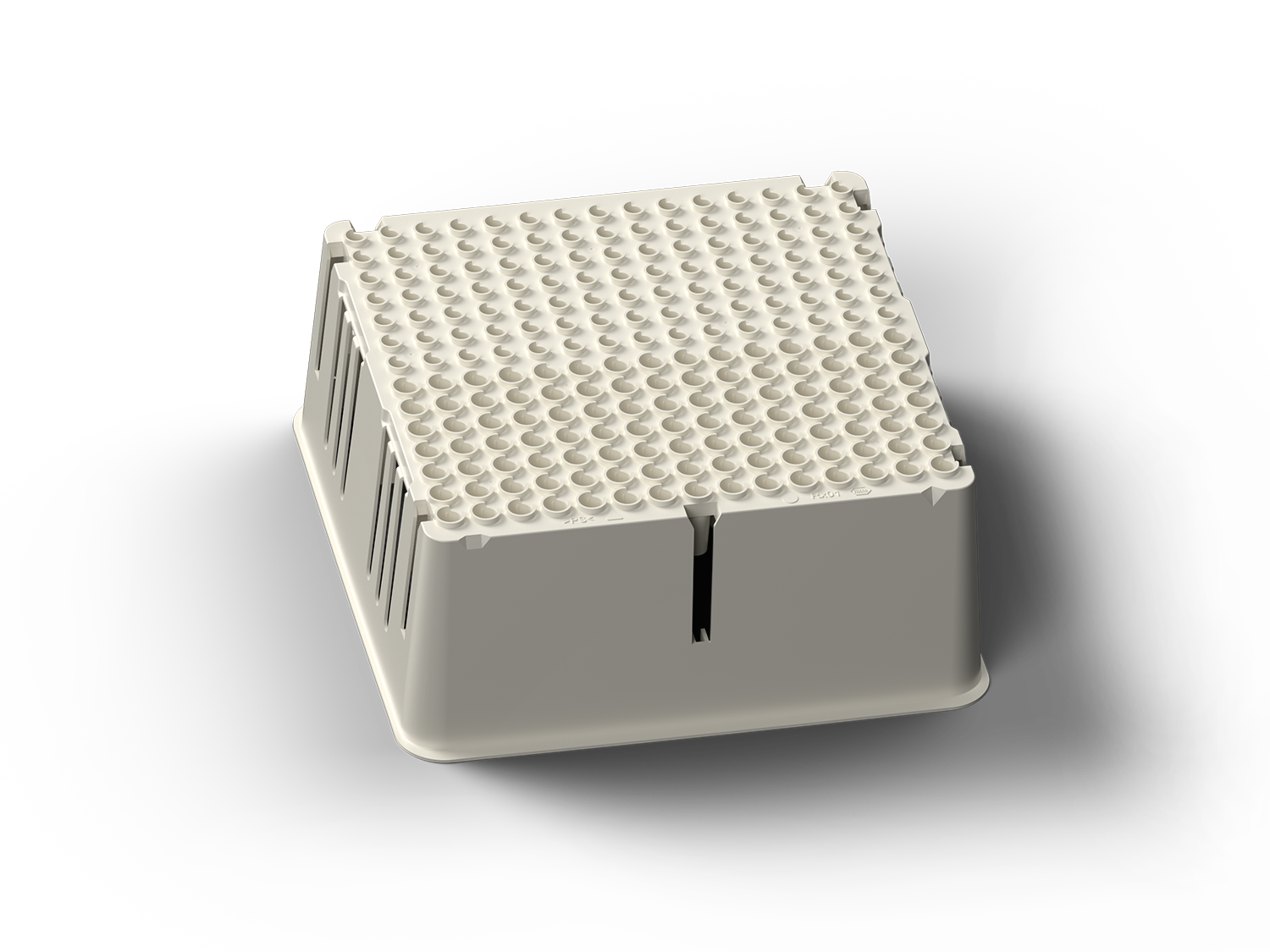

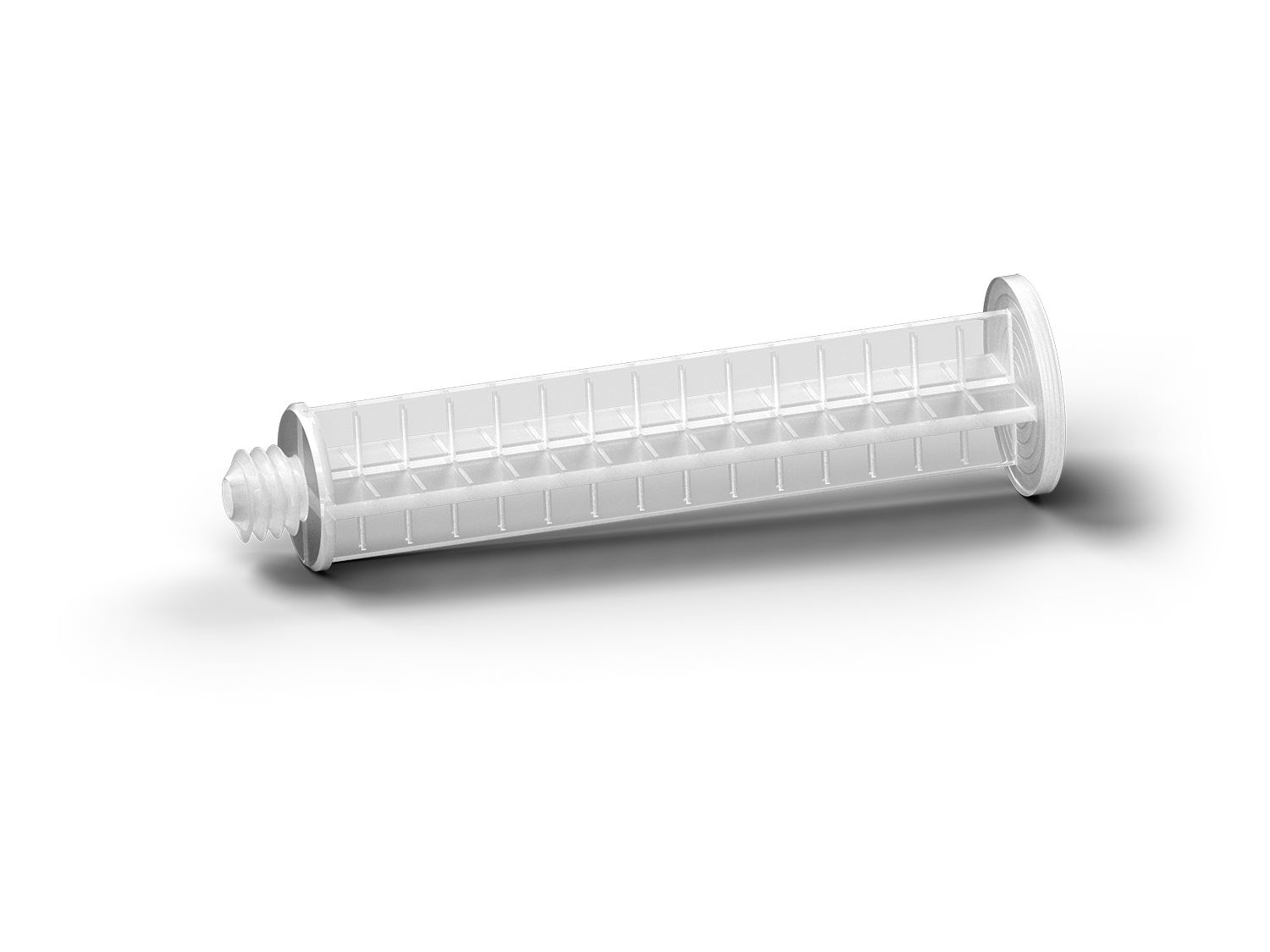

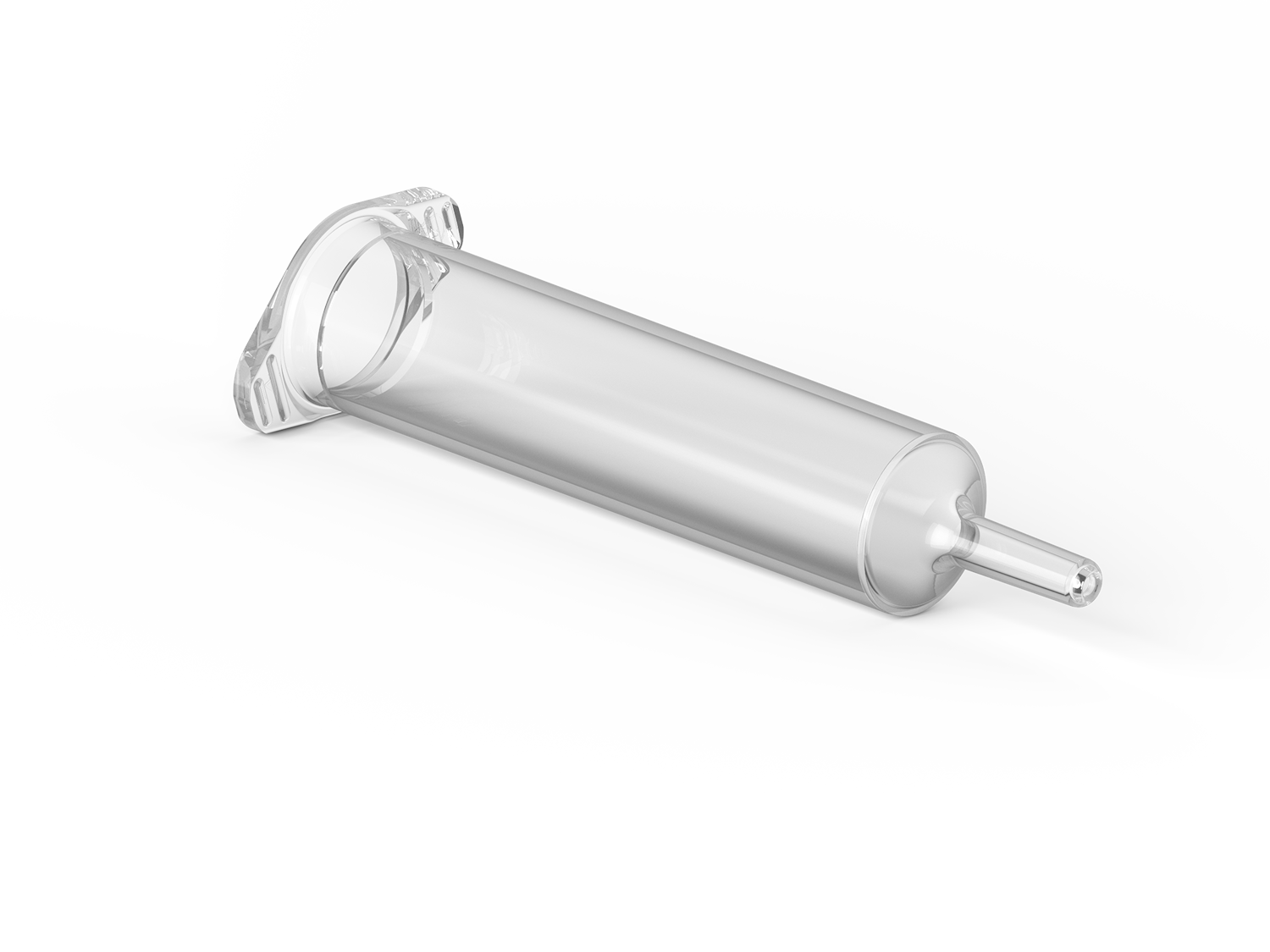

As a result, demanding customers find in us an innovation-driven partner with a holistic range of capabilities, one who anticipates technical challenges and consistently pursues the goal of securing our clients’ long-term success. Our tools are used across a wide variety of medical applications, including the production of laboratory utensils, syringe barrels, plunger rods, cartridges, blood collection tubes, racks, luer components, and drip chambers, where they deliver maximum precision, outstanding process stability, and consistently reliable product quality.

THENextGenMOLDMAKER